The Productivity Engine: How Digital Twins Bridge the Real and Virtual Worlds for Operational Excellence

The Concept: Defining the Dynamic Replica

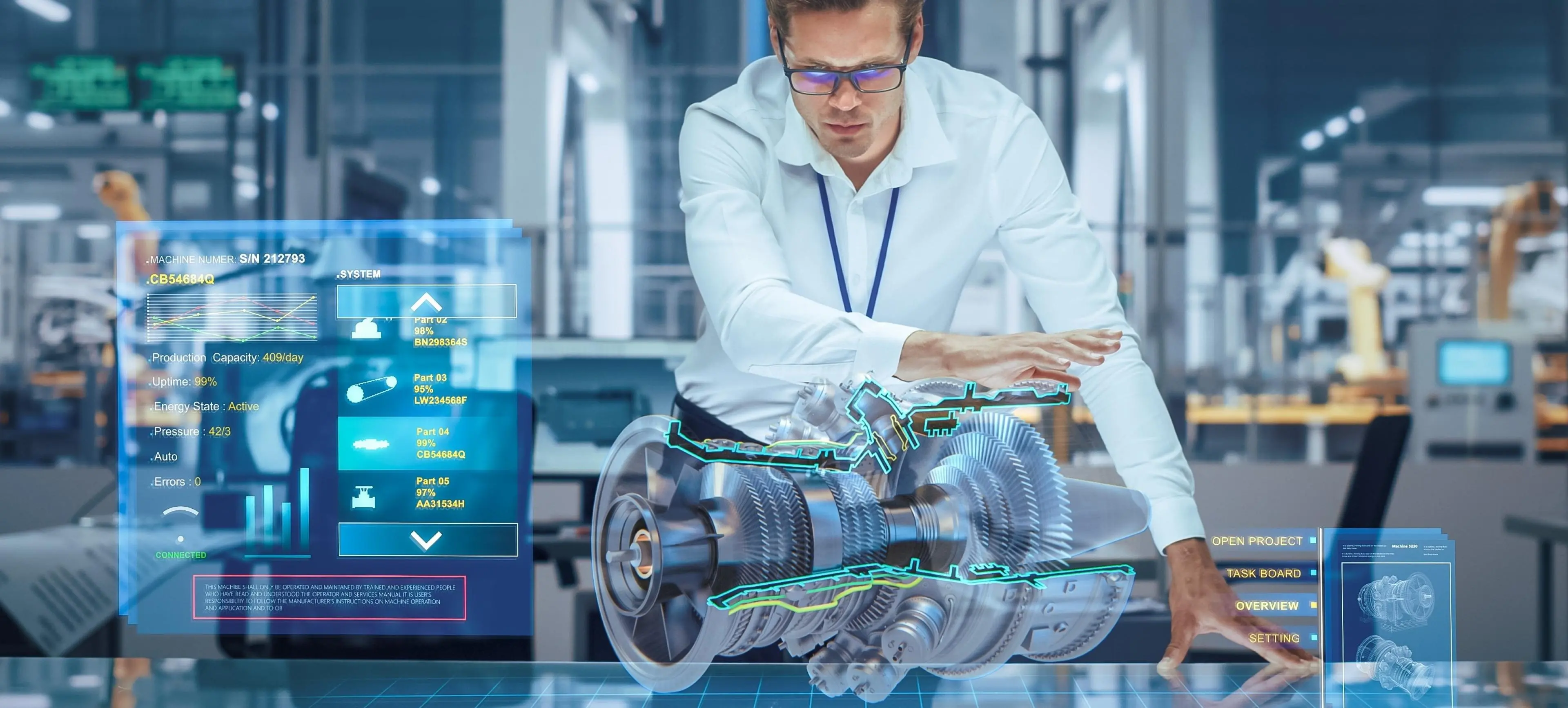

In the age of Industry 4.0, a fundamental shift is occurring in how physical assets, processes, and systems are managed: the rise of Digital Twin (DT) technology.

A digital twin is a dynamic, virtual replica of a physical counterpart, created using a software program that continuously collects real-world data.1 This constant, real-time linkage between the physical product, the virtual model, and the data flow cycle is what makes the technology so transformative.1 By enabling high-fidelity virtual simulations, the digital twin can accurately predict the performance, status, and potential anomalies of its physical equivalent.

Driving Productivity: The Shift from Reactive to Predictive

The core value proposition of a digital twin is its ability to transition enterprise strategy from reactive damage control to proactive, data-driven optimization. This shift unlocks massive improvements in productivity and operational efficiency across the entire lifecycle of an asset or system.

1. Eliminating Unplanned Downtime with Predictive Maintenance

Perhaps the most critical driver of operational productivity is Predictive Maintenance (P-M). By continuously monitoring the condition of machines using integrated IoT sensor data, digital twins can forecast when maintenance will be required before any component failure occurs.3

This capability is far more advanced than traditional scheduled or condition-based maintenance, allowing organizations to optimize operations, minimize unplanned downtime, and precisely extend the Remaining Useful Life (RUL) of products through continuous testing and optimization. In a factory setting, the twin can virtually test and optimize various maintenance policies—from scheduled to predictive—to ensure the most efficient production line operations.

2. De-Risking and Accelerating Design

In the design and engineering stages, digital twins eliminate the time and cost associated with building and testing expensive physical prototypes.

- Virtual Prototyping: The as-designed twin is rigorously tested using sophisticated simulations for validation studies and real-world performance prediction, allowing teams to converge complex physics models in a cohesive virtual environment.3

- “What-If” Analysis: Teams can execute comprehensive scenario planning, testing new operational policies or assessing external risks—such as the impact of flood risk on infrastructure or optimizing staff numbers in a hospital—in a safe, virtual sandbox environment before committing resources or risking actual asset damage.

The Technology Stack: Architecting the Virtual Replica

A functional, predictive digital twin is built upon the seamless integration of five advanced technology layers:

| Technology Layer | Function in the Digital Twin | Productivity Impact |

| Internet of Things (IoT) | The foundation; continuously gathers real-time data from the physical asset via sensors. | Provides the live fidelity necessary for accurate real-time decision-making. |

| Simulation & Modeling | The core; creates the virtual replica and defines its physics-based behavior using Multiphysics Simulation. | Enables accurate prediction of failure, performance, and behavior. |

| Artificial Intelligence (AI) / ML | The intelligence; processes massive datasets, interprets trends, forecasts anomalies, and facilitates automated decision-making. | Translates raw data into actionable maintenance and optimization strategies. |

| High-Performance Computing (HPC) | The engine; provides the massive computational power needed to run complex, interdependent simulations rapidly. | Ensures simulations run fast enough to be relevant for real-time operational control. |

| 5G and Edge Computing | The connectivity; 5G provides the ultra-low latency and high bandwidth necessary for real-time control (like autonomous vehicles) and high-quality Augmented Reality (AR) visualization. Edge computing speeds up response times by processing data locally. | Allows for near-instantaneous remote control and immersive field assistance for workers.5 |

This convergence eliminates information silos, ensuring that multidisciplinary project teams—from engineers to field technicians—all work from a single, dynamic source of intelligence.

Transforming Key Industries

Digital twin technology is rapidly moving from niche application to critical infrastructure across major industrial sectors:

Manufacturing and Industry 4.0

The manufacturing sector uses DTs to achieve precision monitoring, advanced quality control, and superior production optimization.5 DTs monitor production lines and machinery in real-time to reduce defects. For example, specific implementations use Deep Learning (DL) techniques to monitor critical parameters in machines, allowing the DT to predict potential anomalies and generate maintenance strategies to prevent unexpected system downtime, thereby ensuring superior quality in the final product.2

Also read:

- Innobles Smart Technologies: Your Partner in Agentic Transformation

- Emerging Trends in AI and Government Policies

- Cloud Data Encryption Guidefor IT Professionals

- Innobles Smart Technologies: Your Partner in Agentic Transformation

Healthcare and Personalized Medicine

Digital twins hold the potential to revolutionize patient care and hospital administration, resulting in improved patient outcomes and reduced costs.13

- Operational Efficiency: DTs analyze historical and real-time hospital data to optimize staff schedules, manage operating room vacancies, and detect critical resource shortages, resulting in streamlined clinical operations and cost reductions.

- Personalized Medicine: Sophisticated replicas of a patient’s body systems track persistent conditions, allow doctors to discover pathologies earlier, and enable them to experiment with treatments and prepare for complex surgeries virtually.

Automotive and Transportation

The Automotive & Transportation sector is a significant adopter of this technology, driven by the high complexity of R&D, including Electric Vehicle (EV) design and component optimization. Digital twins create virtual vehicle models that provide insight into the physical, software, mechanical, and electrical behavior, making predictive maintenance invaluable for complex vehicle systems.

Architecture, Engineering, and Smart Cities (AEC)

DTs scale up to model entire urban environments and infrastructure projects. By integrating with existing models like Building Information Modeling (BIM), DTs accelerate construction timelines, enable remote maintenance inspections, and support long-term operational management.12 A key example is the Virtual Singapore project, a national-scale 3D model that enhances governance by enabling city planners to visualize and interact with the urban landscape in real-time to optimize land use, assess flood risk, and manage underground utilities.8

Conclusion

Digital twin technology is the engine that drives modern operational excellence. By creating a continuous feedback loop that fuses real-world data with predictive simulation, it empowers organizations to make proactive, intelligent decisions that minimize cost, mitigate risk, and maximize productivity. As this technology becomes more accessible through platforms that provide pre-built tools and cloud-based solutions, the digital twin is quickly becoming the indispensable operating framework for the future of industry.